Product Description

The Power Drawbar is a CNC-class pneumatic system that automates the task of loosening and tightening the drawbar when changing a tool on a milling machine. This expedites the tool changing process and adds a great deal of convenience.

If a Power Drawbar system is not offered on your specific mill, the Build Your Own Power Drawbar Kit may be the answer. This kit includes components common to the Power Drawbar system. Mill-specific items are provided by the user. Experience in precise measuring, drawing/drafting, and machining are necessary to complete the Power Drawbar system.

A design and fabrication package is also available for adapting the Power Drawbar system to your specific mill for a turnkey solution.

Components Provided by Priest Tools

- Pneumatic multi-stage cylinder and fittings

- Cylinder plate and mounting hardware

- Pneumatic valve, fittings, and air tubing

- Electrical assembly and parts

- Actuator plate package

- Belleville springs and flange package

- Power Drawbar R8 3/4″ collet

- Drawing of cylinder plate for designing support plate

- Guidance for making the support plate

- Guidance for designing the drawbar

- Installation guide

Components Provided by the User

- Support plate and mounting hardware

- Drawbar

Requirements

- Compressed air supply of 90-120 psi.

- 3/4” quick change tooling system such as the Tormach TTS

Feasibility

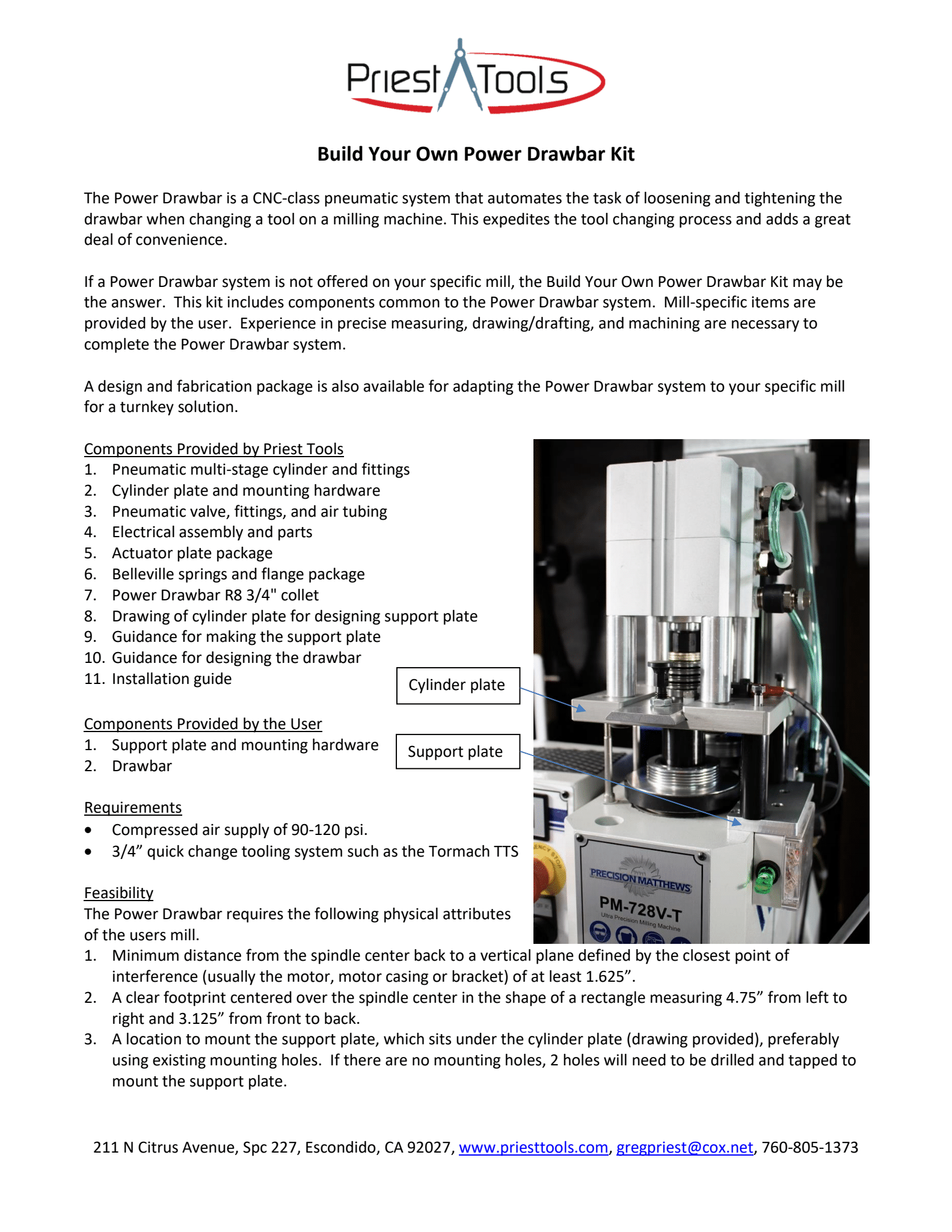

The Power Drawbar requires the following physical attributes of the users mill.

- Minimum distance from the spindle center back to a vertical plane defined by the closest point of interference (usually the motor, motor casing or bracket) of at least 1.625”.

- A clear footprint centered over the spindle center in the shape of a rectangle measuring 4.75” from left to right and 3.125” from front to back.

- A location to mount the support plate, which sits under the cylinder plate (drawing provided), preferably using existing mounting holes. If there are no mounting holes, 2 holes will need to be drilled and tapped to mount the support plate.

Key Features

- Bolt-on accessory requiring no modification to the mill (except perhaps the Build Your Own Drawbar Kit).

- Changes tools with the flip of a switch.

- Uses a compression design found in commercial machining centers isolating the load from spindle bearings.

- Features a safety activation/lockout feature.

- Works with milling machines that have a quill.

- No machining of drawbars required (except Build Your Own Drawbar Kit).

- May be integrated with CNC control programs such as Centroid Acorn or Mach3.

- Compatible with other Priest Tools mill accessories on select mills including Quill Stop, Spindle Brake and Power Lift.

Simple to Use

Insert the actuator plate into the cylinder plate and release the spring plunger that locks it into place. Then flip the switch up to activate the system and remove the tool from the collet. Insert another tool into the collet, and then flip the switch down to dis-engage the Power Drawbar and secure the tool for machining.

Video: https://www.youtube.com/watch?v=r5c5YHj2p5U&t=23s

The Power Drawbar is available on the following milling machines.

| Precision Matthews | Little Machine Shop | Grizzly |

| PM-25MV | 55xx | G0463 |

| PM-30MV | G0619 | |

| PM-727M & V | G0704 | |

| PM-728VT | ||

| PM-833VT | ||

| PM-940V & M |

The Power Drawbar has been adapted on the following milling machines.

- Alliant RT-2 (Sharp LMV-49, similar to Bridgeport)

Design and Fabrication Package

This package includes creating the design and fabrication of the support plate and drawbar. All hardware for mounting the support plate to the mill and cylinder plate is also included. The user must be skilled at taking accurate measurements to .001” of the top of the mill headstock as input to creating the support plate.

User provides:

- Photos of the top of the headstock at about a 45 degree angle of left, front and right sides.

- Accurate measurements to .001” of the top of the mill headstock including the spindle center and potential mounting hole locations for the support plate, and the front, side, and back edges of the headstock.

- Test fitting of the support plate and Power Drawbar system providing feedback to Priest Tools.

Priest Tools provides:

- Power Drawbar support plate with final drawing.

- New drawbar compatible with the new Power Drawbar system.

- All hardware for mounting the support plate to the mill and to the cylinder plate.

Video: https://www.youtube.com/watch?v=r5c5YHj2p5U&t=23s

Brochure