Product Description

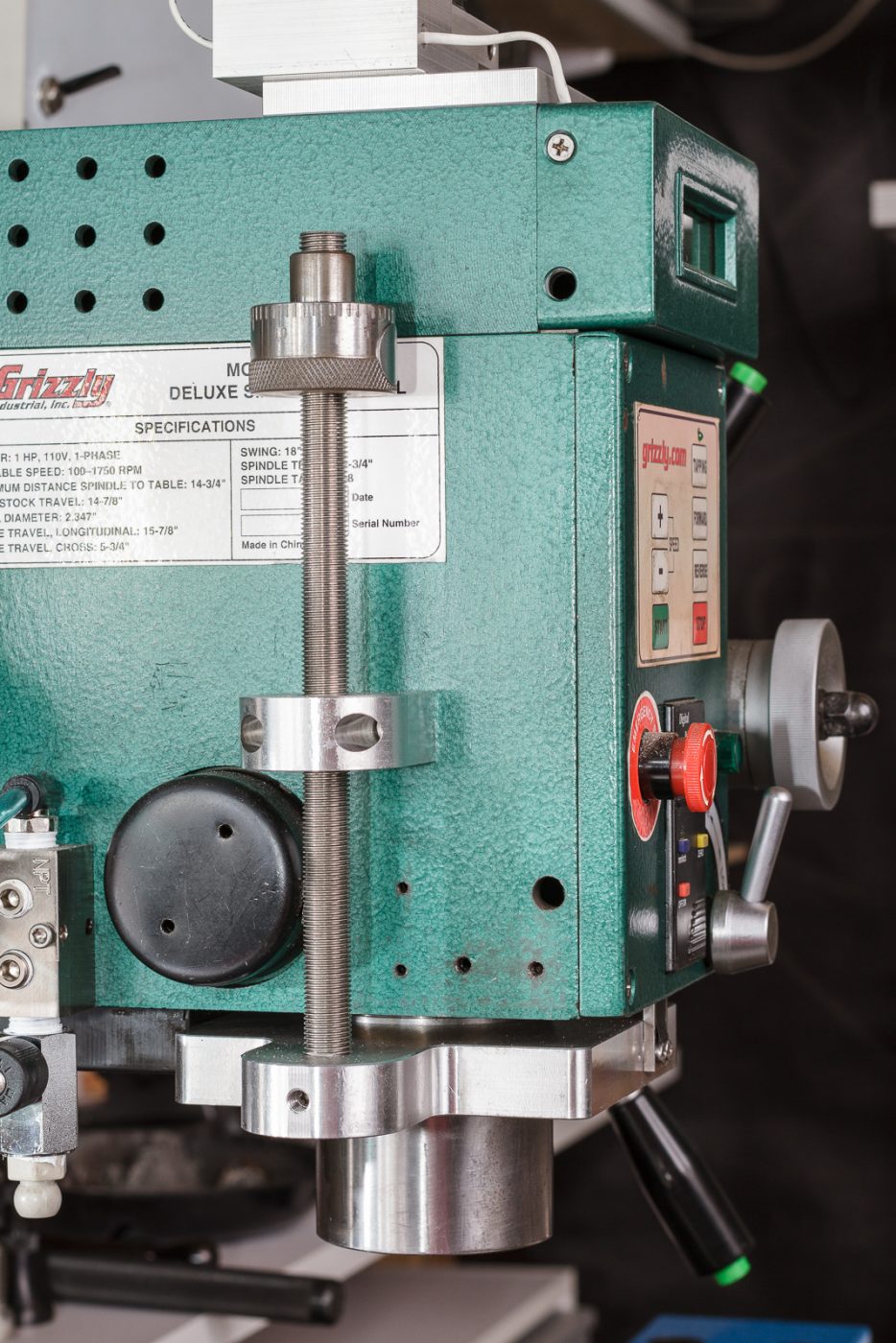

The Quill Stop provides a quick and accurate way to set the quill depth of cut on Grizzly G0619 and G0463 and all Sieg X3 and SX3 mills.

Simple to Operate

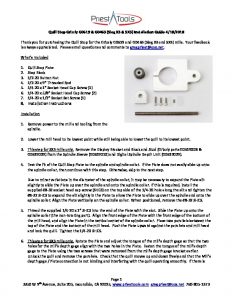

- Simply press the button and the nut disengages from the thread

- Slide to desired position and release the button to engage the threads

- Turning the 1/2-20 UNF nut then allows for precision micro-adjustments of depth of cut

Useful in Many Ways

- The primary purpose of the Quill Stop is to set an accurate and consistent depth of cut for repeated machining operations including boring, chamfering, and milling.

- The Quill Stop is also very handy in performing single or repeated chamfering of parts. To setup the chamfer the first time on a part, turn the mill off and simply lower the cutter to the top of the part, lock the fine feed knob, and back-off one full turn (turn the Button Nut clockwise as viewed from the top). Then start the mill and turn the Button Nut on the Quill Stop counter clockwise in small increments until the cutter contacts the part. Then continue turning the Button Nut counter clockwise and alternately lowering the quill until the desired chamfer is achieved.

- The Quill Stop works equally well performing inside chamfers using typical chamfering mills, and outside chamfers using, for example, a hollow mill.

Features

- Installs in minutes

- Requires a slight modification to the mill (drill & tap 2, 1/4-20 holes in the side of the machine head)

- Made to exacting specifications in precision machining centers

- The main plate and stop block are made of 6061-T6511 Aluminum

- Made in the USA

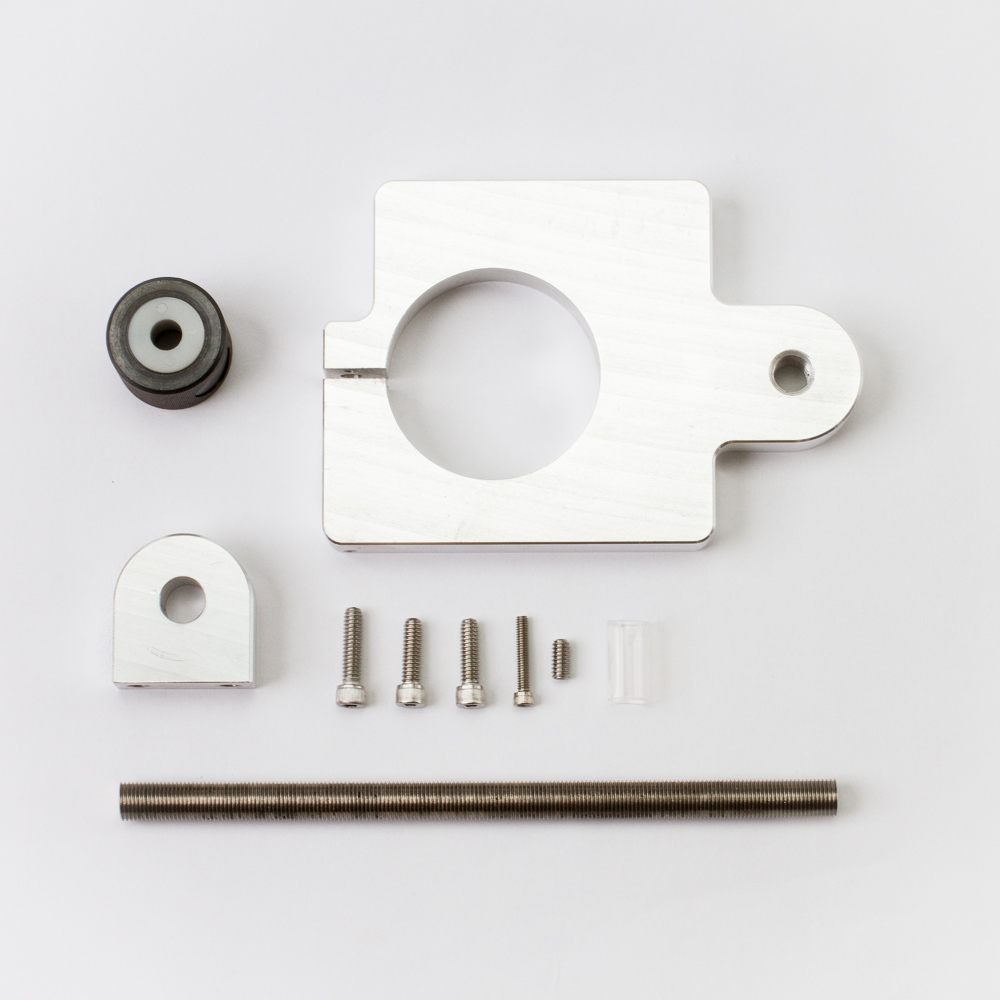

What’s Included

- Quill Stop Plate

- Stop Block

- 1/2-20 Button Nut

- 1/2-20 x 9” Threaded Rod

- 1/4-20 x 1” Socket Head Cap Screw (1)

- 1/4-20 x 5/8” Socket Head Cap Screw (2)

- 1/4-20 x 1/2” Socket Set Screw (1)

- Installation instructions

Related products

$779.00 – $979.00

$779.00 – $979.00

$209.00