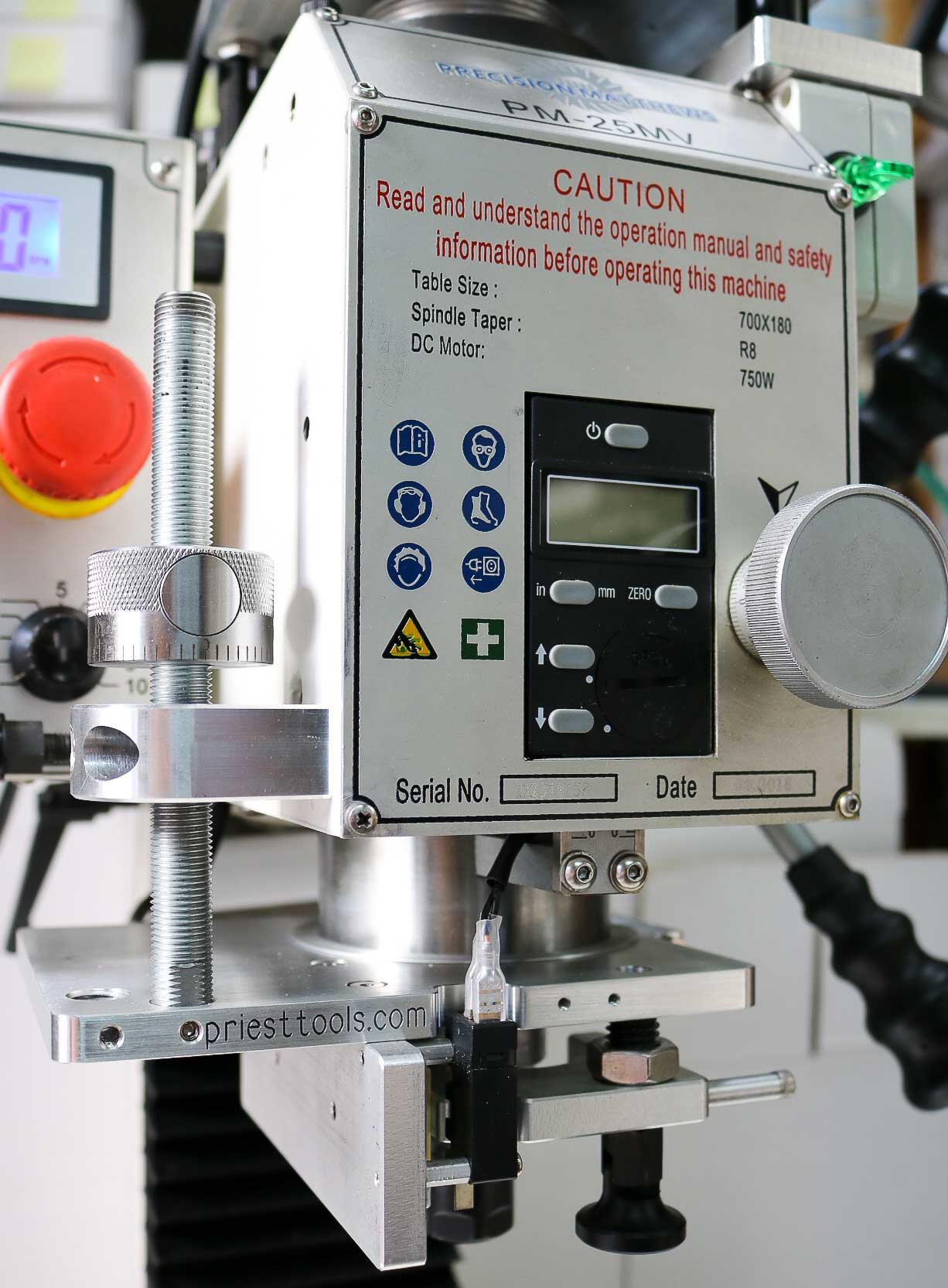

Spindle Brake PM-25MV

$209.00

The Spindle Brake Flip provides a convenient method of locking the spindle freeing both hands to complete a tool change. A safety switch ensures that power to the motor is disabled when the Spindle Brake is engaged. This Spindle Brake features a locking fork which locks the mill’s spindle when engaged and does not require a separate locking device to be mounted and removed from the mill.