Quill Stop PM-25MV

$179.00

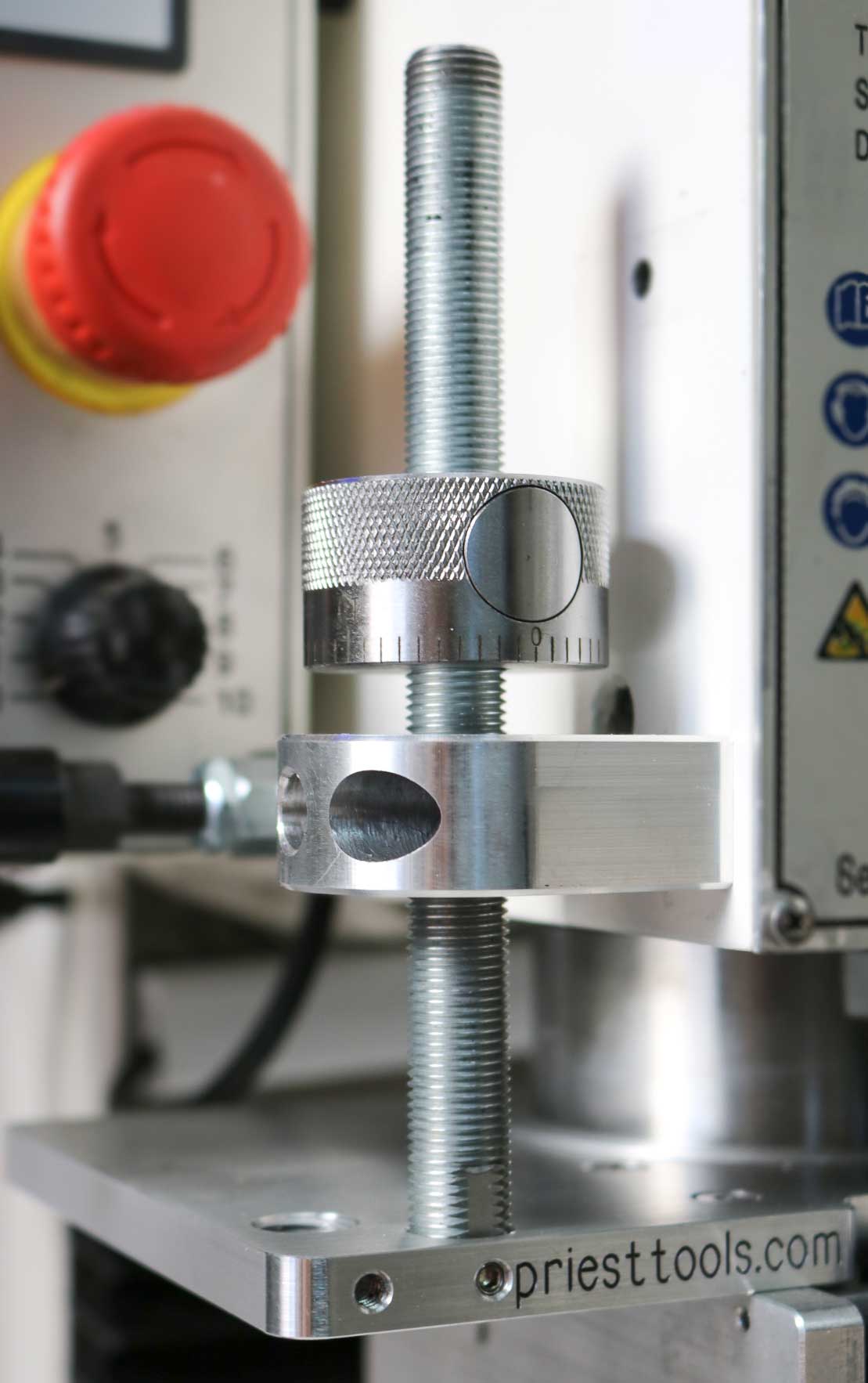

Installation of the Quill Stop requires the chip guard and its switch enclosure be removed from the mill. The Quill Stop-stop block is mounted in the lower hole vacated by the chip guard switch enclosure.

The Quill Stop provides a quick and accurate way to set the quill depth of cut on the Precision Matthews PM-25MV and all compatible milling machines.

A key feature of the Quill Stop is that it is compatible with the Spindle Brake for the PM-25MV mill. The Spindle Brake PM-25MV locks the spindle for performing tool changes and features an electromagnetic locking mechanism which locks the spindle and cuts power to the mill when engaged for additional safety, much like pressing the E-Stop switch when changing a tool.