Product Description

The Quill Stop provides a quick and accurate way to set the quill depth of cut.

Features

- A bolt-on accessory requiring no modification to the mill.

- A precision button nut with .001” graduations is included.

- Compatible with the Quill DRO for this mill.

Simple to Operate

- Simply press the button and the nut disengages from the thread.

- Slide to desired position and release the button to engage the threads.

- Turning the nut then allows for precision adjustments to depth of cut.

Useful in Many Ways

- The primary purpose of the Quill Stop is to set an accurate and consistent depth of cut for repeated machining operations including boring, chamfering, and milling.

- The Quill Stop is also very handy in performing single or repeated chamfering of parts. To set up the chamfer the first time on a part, turn the mill off and simply lower the cutter to the top of the part, lock the fine feed knob, and back-off one full turn (turn the Button Nut clockwise as viewed from the top). Then start the mill and turn the Button Nut on the Quill Stop counterclockwise in small increments until the cutter contacts the part. Then continue turning the Button Nut counterclockwise and alternately lowering the quill until the desired chamfer is achieved.

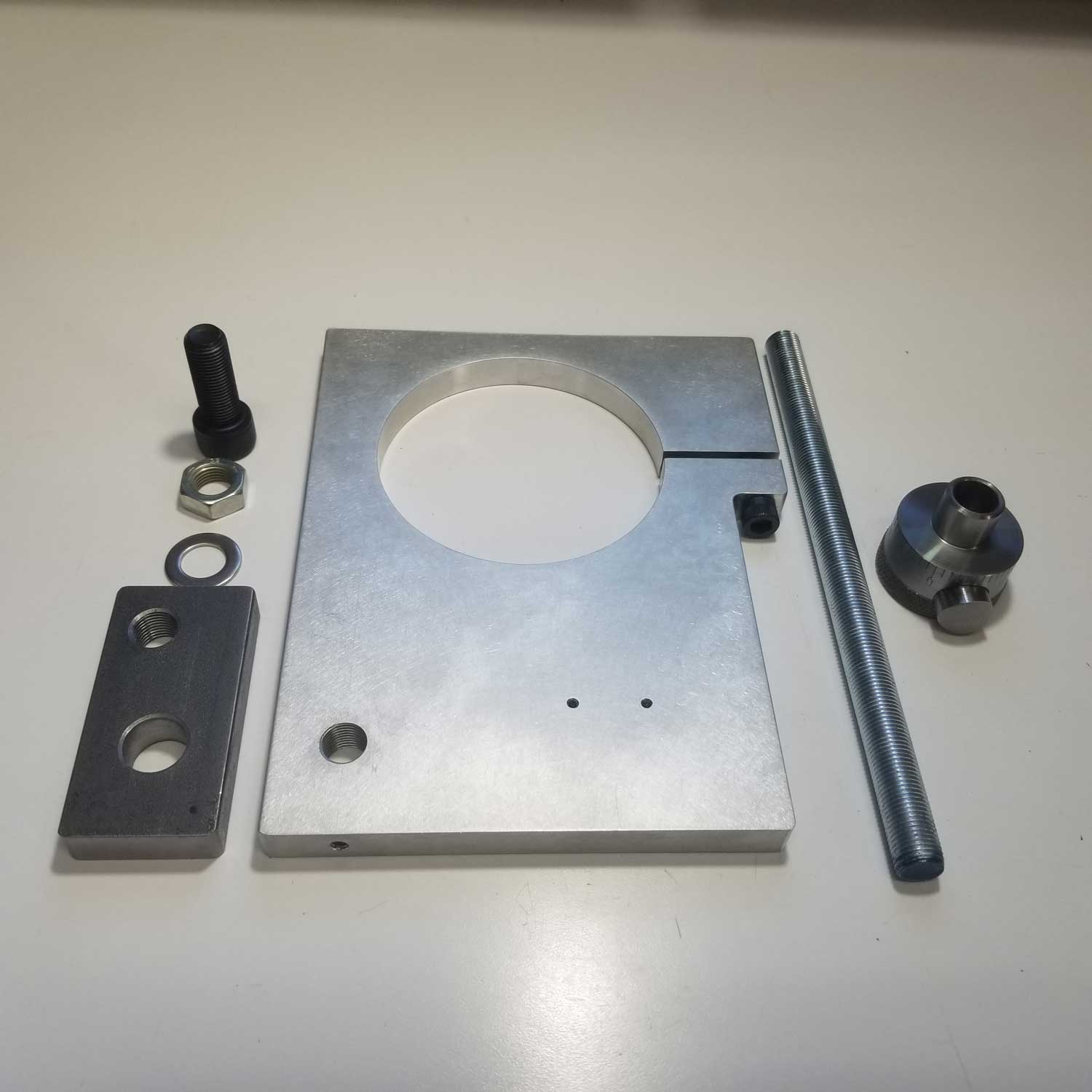

What’s Included

- Quill plate

- Stop Block

- Button nut

- Threaded Rod, Zinc, 1/2″-20 x 8″

- 1/2-20 x 1.375 socket cap screw

- 1/2-20 jam nut

- .515x.875x.06 SS washer

- Socket set screw, 10-24 x 1/4″

Documents – Quill Stop Precision Matthews PM-833TV Installation Guide

Brochure Installation Guide